News, Insights, and more on Industrial IoT

Industrial specialty chemicals are vital to so many industrial businesses. With industrial chemicals, we have the ability to develop quality products through highly efficient processes. Our factories, production facilities, and oil wells simply wouldn’t be the same without chemicals.

One way that chemicals directly drive better business outcomes for manufacturers is production assurance. Chemicals enable us to eliminate byproduct build-ups, minimize hydrate accretion, and prevent machine downtime that would otherwise drastically reduce output.

However, administering chemicals across critical infrastructure is difficult under the current status quo of chemical management operations. Manufacturing processes are fast-moving and dynamic. Today’s chemical treatment programs often fall short, which leads to organizations missing baseline production level targets. Operational managers need real-time visibility into chemical performance, as well as automated tools that adapt to ever-changing chemical needs.

Here, we highlight the negative consequences of having an improperly tuned chemical injection system when it comes to production assurance. Then, we share suggestions to help chemical program managers address common problems that tend to hold back production capacity.

Every major industrial market segment is trying to produce something to meet consumer demand. If production slows, lead times increase, consumers get frustrated, and revenue disappears. Companies use industrial chemicals to improve production assurance so that they can keep up with demand.

Let’s take a look at a few examples of what happens when our chemical injection systems don’t work as intended.

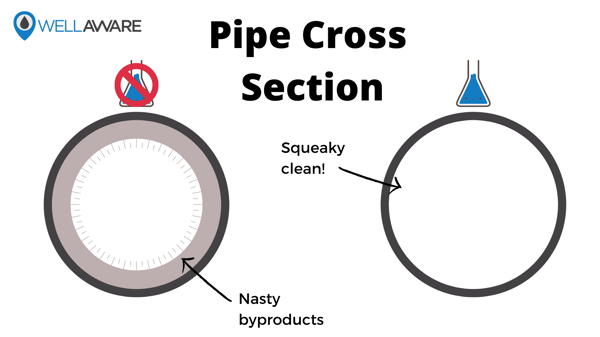

Without specialty chemicals, production pipelines can get coated with

byproducts, like scale or asphaltene, that reduce production throughput.

We use chemical inhibitors to help prevent the formation and precipitation of unwanted byproducts, like scale, paraffin, and asphaltene, that would otherwise reduce productivity.

If chemical systems under-inject inhibitors, byproducts are free to accrete. In pipelines, byproducts can build up enough to slow down flow rates significantly. If inhibitors are over-injected, they can create expensive downstream and refining consequences.

In industrial fluid processes, it’s not uncommon for water-based hydrates to form and crystallize. Hydrate inhibitors prevent potential crystallization and keep infrastructure free from obstruction. If chemical injection systems don’t deliver enough hydrate inhibitor, water crystals can block vessels or lead to mechanical failures. If systems deliver too much of a hydrate inhibitor, they can turn corrosive and ruin certain components, like gaskets and hoses.

In the petroleum industry, companies spend $5M-15M each year on hydrate prevention, recognizing that shut-in production wells can equate to billions of dollars in lost revenue. On top of that, getting rid of hydrate plugs can cost millions.

Chemical managers need lubricants (e.g., engine oil) for dynamic mechanical processes to minimize heat production and prevent dangerous fires. When lubricants are under-applied, machines can overheat because there is too much friction between moving parts. On the other hand, over-applying lubricants can cause seal failures and fluid friction.

One MIT study found that poor lubrication costs the U.S. $240B annually, which includes both downtime and subsequent machine repairs. Overall, the examples here illuminate the economic and operational costs of applying chemicals inappropriately.

As you can see, improper chemical dosing can wreak havoc on production capacity and financial performance. Rather than throw additional manpower and resources at chemical treatment issues, industrial organizations need to focus their energy where it matters most.

At WellAware, we’ve collected chemical management data from thousands of sites all over the world to study how operations leads can improve treatment systems without overburdening their teams. Below we’ve identified two common issues with chemical programs that hinder production assurance - and how to solve them.

According to our baseline data, 1 in 15 industrial chemical tanks is empty at any given time.

In chemical systems, we store chemicals in industrial tanks and then inject those chemicals into manufacturing process streams using pumps. However, many industrial organizations inadvertently allow chemical tanks to go empty, which means pumps can’t deliver chemicals where and when they are needed.

Though this may seem obvious, one of the best ways to assure production levels is by keeping tanks full. When tanks go empty, injection pumps can’t treat essential infrastructure with the chemicals needed to prevent byproducts from building up, hydrates from forming, and machines from breaking down.

Maintaining tank supply sounds simple, but it’s not, especially for those with distributed inventories. It can be hard to stay on top of tank levels across large factory floors and sprawling oil fields. In fact, according to our baseline data, 1 in 15 chemical injection tanks is empty at any given time - that’s not good.

An easy way to lessen this problem is to install tank level monitors in every tank. Tank level monitors can indicate when you have an empty tank, which is helpful. But, this is only part of a robust solution. You need to know before your tanks are empty, not when they are empty, giving you time to restock.

Chemical managers need to know both the current volume of a tank and the rate at which chemicals are used in order to project future “empty dates.” With ample planning, workers can avoid stockouts and prevent chemical systems from missing treatment.

At WellAware, we calculate projected empty dates far in advance based on tank level readings and measured usage. As a result, clients can prioritize tanks by chemical type and optimize fill schedules according to their unique chemical management programs.

Pump failures are a chemical manager’s worst nightmare. In chemical injection systems, we need pumps to deliver chemicals directly to the point of need. Without them, chemical treatment doesn’t work, regardless of whether you’ve optimized tank monitoring practices.

And the reality is that pump failure is quite common. In fact, our baseline data suggests that more than half of pump downtime occurrences last longer than 24 hours. And worse, 4 out of 5 industrial assets have gone untreated for a period of 24 hours or longer in 2020. Industrial organizations simply can’t allow this to happen.

When it comes to injection pumps, there are two main failure modalities: power failures and air lock.

Most injection pumps are powered by DC (solar) or AC systems. If a pump loses power, or if a power system degrades, motors can’t draw the current needed to inject chemicals. Consequently, operators have to closely monitor pump power and perform diagnostics regularly.

But, here’s the catch - many monitoring systems will “go dark” when pumps lose power because they rely on the same power sources. As a result, operational managers need monitoring capabilities that are powered by long-lasting, independent sources.

For example, in our WellAware On Demand Chemical™ service, every device we use has internal backup batteries that can last independently for years. Our platform also recognizes all power failures that occur across a manufacturing operation and immediately informs managers when pumps go down.

The second primary cause of industrial pump failures are air locks. This problem is particularly nefarious and is closely related to the empty tank issue described above.

When tanks run empty, injection pumps draw against a vacuum and pull air into injection lines. When the tank is refilled, you’d expect the issue to resolve itself, right? Nope.

Air bubbles often get trapped, because the pressure created by the vacuum prevents the pump from pushing the air bubble through the pipeline. The pump needs to be purged completely to open the line for chemical treatments.

Doing so takes a lot of manual effort, which is why we designed WellAware On Demand Chemical™ to detect existing air locks and remotely purge injection lines. Rather than visit pumps and manually extract air bubbles through feed lines, operators can unblock the line from the comforts of their office or trucks!

With these fixes, chemical managers can proactively prevent common chemical injection problems and ensure assets get the appropriate treatment needed to maintain production throughput. And using a service like WellAware On Demand Chemical makes these solutions even easier to implement. For those interested in learning more about our On Demand Chemical™ product line, visit our website at wellaware.us/chemical.

Having a data challenge? You're not alone.

Sign up for our blog and receive a free eBook on the 10 data challenges in Industrial IoT and how to overcome them.

Have a Question?