News, Insights, and more on Industrial IoT

As we all know, water is critical for oil and gas well completions. According to the USGS, a single frac job could need up to 16 million gallons of water.

As we all know, water is critical for oil and gas well completions. According to the USGS, a single frac job could need up to 16 million gallons of water.

Of course, we’ve been fracturing during completions for well over a decade now, so why the focus on water?

We’ve covered ESG extensively in our content, but for those who aren’t in on it, ESG stands for “Environmental, Social, and Governance” - it’s a term that in essence defines what investors look for in companies to choose how to invest their capital “sustainably.”

Water use matters to investors

Oil and gas producers seeking capital to ramp up drilling programs in the absence of free cash will need to score well on critical ESG metrics to get access to the best funds.

Behind greenhouse gas emissions, water use is the penultimate measure of an oil & gas producer’s sustainability, and it’s certainly jostling for first.

We all learned the “Three Rs” when we were young: Reduce. Reuse. Recycle. If companies can’t demonstrate that they are reducing freshwater reliance, reusing produced water for completions, and recycling flowback water back into frac streams, they’ll miss out on the funds they need to drill. It’s that simple.

This critical reality - that effective water management is a prerequisite for access to cash - puts oilfield water services companies in a great position. Not only is drilling activity ramping up (nearly 3x the number of active rigs over the pandemic low), but oilfield water management companies can command higher premiums for services that give their customers a stronger ESG platform. The market is growing, and the margins along with it.

Of course, where markets swell and margins widen, competition swoops in. Oilfield water management companies, both newcomers and the old guard, will need to outpace their competitors to cash in on this groundswell.

And how will they do this? We believe that the most successful oilfield water management companies will outpace their competition in 4 key areas:

Which brings us to the main point of this article: Oilfield water services companies should automate their operations. Automation enables success in each of these 4 areas, as we’ll discuss below.

During oilfield booms, services companies have the ability to rake in tremendous profits. Assuming they offer a well-differentiated service, their growth is only limited by their ability to expand and extend their operations to serve more customers.

While the US oil industry may not be booming, per se, it’s certainly experiencing sustained expansion that should continue for at least 18-24 months.

Most oilfield services companies think of efficiency in terms of creating distance between top line revenues and bottom line costs. In this mindset, efficiency becomes a pure margin play.

But when the market is growing as it is, oilfield services companies should seek efficiencies so that they can expand their share of the market.

Automation allows oilfield services companies to cover more ground with fewer resources so they can grow their market share without significant investment in personnel.

During a time when good people are hard to come by, doing more with less becomes the imperative for every oilfield services company, water management included.

By automating non-critical tasks such as data gathering, pump control, and reporting, oilfield water services companies can free up more time to focus on growing accounts and seeking new business.

Oilfield culture is safety culture. In this industry, if you can’t maintain a strong safety record, you lose work, plain and simple. Contractor safety reflects on the customer, so customers won’t keep unsafe contracts around. This means that oilfield water services companies should be obsessing over metrics like TRIR and Near Misses.

Automation helps oilfield water services companies keep their people safer.

Driving is the most unsafe activity that oilfield service technicians engage in every day. Automation reduces windshield time by eliminating data gathering missions.

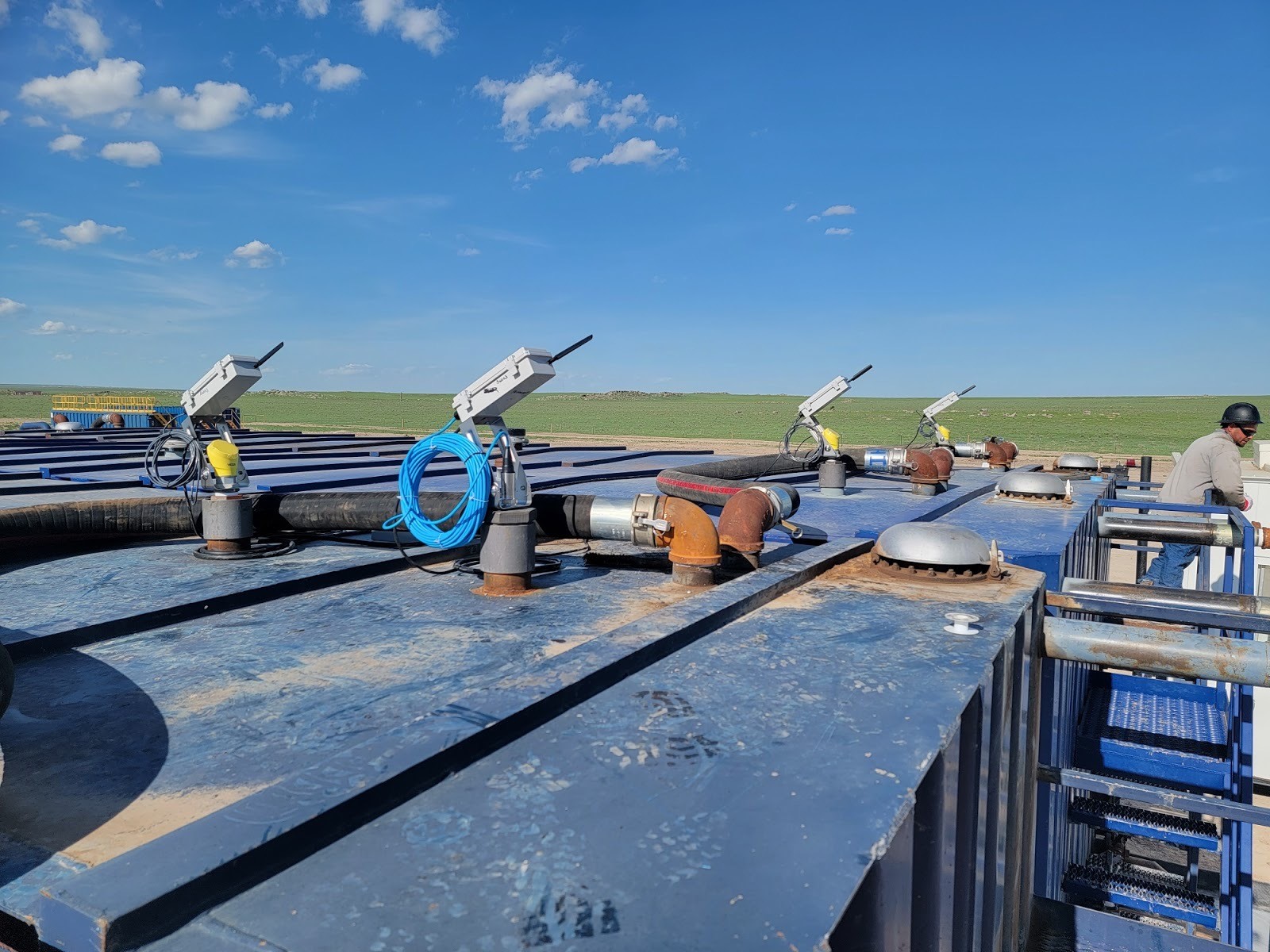

Even simple things like installing frac tank level gauges with remote HMIs can keep technicians from climbing on top of tanks - a practice which creates slip risk, fall risk, and H2S exposure risk.

Put simply, automation gives field workers more information to make safer decisions, which results in lower incident rates and happier customers.

Driving is the most dangerous activity for oilfield technicians every day and account for the largest portion of field-related safety incidents.

Remember ESG? Well it’s not just for oil and gas operators - it’s for their service companies too. Service companies that can achieve - and measure - sustainability improvements earn kudos with accounts that need to maintain a squeaky clean ESG image.

Automation helps oilfield services companies both achieve better sustainability measures, which reflects positively on their customers.

For starters, reductions in windshield time don’t just impact safety, they also result in lower overall emissions. Fewer miles driven means a lower carbon footprint, which large producers appreciate.

Aside from emissions reductions, automation can contribute to reduced resource consumption, less waste, and fewer leaks and spills.

But the benefits don’t stop there. Automation doesn’t just make it easier to achieve better sustainability; it makes it easier to measure it, too.

Producers love to measure and report on their sustainability impacts. Imagine how much customers might appreciate an oilfield water service company that could measure exactly how much water they helped their customer recycle.

Customer service is the culmination of everything an oilfield water services company does for its customer. Whether its treating, hauling, transferring, or pumping, the best services companies all pride themselves on their ability to solve big problems for their customers.

Efficiency, safety, and sustainability all contribute to stronger customer service, but for the modern oilfield services company, the nature of “customer service” has expanded.

Put simply, oilfield services companies are now expected to be, at least in part, data companies.

What does that mean?

It means that customers now demand that oilfield water management companies provide great customer service through safety, sustainability, and efficiency, but also that they prove it.

Customers are asking their vendors questions like “How fast can you communicate? What data can you give me? What reporting options do you have? Can you integrate into my SCADA?”

Automation gives oilfield water management companies a definitive answer to these questions, and it helps satisfy their customers’ growing appetite for data.

As they say, “data is the new oil.” If oilfield services companies can become data creators and brokers for their clients, they become that much more valuable. Automation allows oilfield services companies to build the data repertoire that results in better stickiness and lower customer turnover.

As oilfield water management companies look to capitalize on the growing market, they’ll have to fend off attacks from competitors at every turn. By enabling better efficiency, safety, sustainability, and customer service, automation can position these companies to win. Those oilfield services companies that incorporate and commit to automation have the opportunity to box out their competitors. Those that don’t risk losing out on market share growth that not only results in more revenue during boom times, but also more resilience during the inevitable bust.

Like what you're reading? Sign up for updates!

Have a Question?