News, Insights, and more on Industrial IoT

Much has been said about the game-changing potential of IoT technology, especially for industrial sectors. For years, IoT vendors have promised “actionable insights”... but, let’s be honest, does anybody really know what that means?

Much has been said about the game-changing potential of IoT technology, especially for industrial sectors. For years, IoT vendors have promised “actionable insights”... but, let’s be honest, does anybody really know what that means?

Operators continue to struggle with the “pilot purgatory” problem; they’re stuck waiting on results to justify moving forward with full-blown IoT solutions. Leaders are holding out, waiting for their

investments in automation, data sharing, and machine learning to translate into new revenue streams and lower costs.

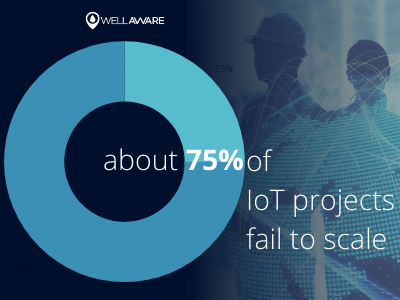

Unfortunately, this just isn’t happening. Research by Deloitte, McKinsey, and many others have shown that at least three quarters of industrial IoT projects get stuck in a pilot phase, often for years.

To put it bluntly, industrial organizations are waiting for the IoT to prove itself and bring about Digital Transformation that actually... well... transforms businesses. But the technology hasn’t lived up to the hype. Not even close. Why?

Our hypothesis is that the IoT needs a higher purpose - one that aligns more closely with global trends and greater humanitarian pursuits. For too long, IoT service providers have pitched the technology as the way for industrial companies to achieve “operational efficiency.” But here’s the thing: most industrial companies are already highly efficient operators by nature.

Leaders are holding out on the IoT, waiting for their investments in automation, data sharing, and machine learning to translate into new revenue streams and lower costs.

The IoT deserves a better calling, and we’ve got some ideas. But first, why hasn’t the IoT made good on its promises?

We often forget that most industrial sectors are decades - or even centuries - old. Many industrial organizations out there today are some of the oldest businesses in the country.

For example, the legendary toolmaking company Ames was founded two years before the American Revolution. The multidisciplinary energy contractor, Whessoe, has been around since the 1790s. The chemicals powerhouse DuPont was founded in 1802, nearly 220 years ago. The list goes on and on.

These businesses have had years and years to fine-tune their operations, and the people running these organizations have been doing their jobs for a long time.

People expected the IoT to come along and revolutionize industrial performance and productivity in significant ways. Given the longstanding, efficiency-oriented legacy of industrial operations, this was a tall order.

Of course, some operators have had success implementing IoT technology within smaller projects. And in a few cases (e.g. fleet management), IoT has provided improvements at scale. However, in a majority of attempts, IoT has been more of an interrupter than a skid-greaser for larger organizations. And while the technology has been associated with environmental sustainability, safety, and similar goals, these have been secondary to the mission of driving efficiency in a space where masters of efficiency already reign.

While the IoT has been associated with environmental sustainability, safety, and similar goals, these have been secondary to the mission of driving efficiency in a space where masters of efficiency already reign.

Do a Google search on “industrial IoT benefits”, and you’ll mostly see results about “improved efficiency” or “reduced downtime” with a little bit of “predictive maintenance” sprinkled in to lure you in. Don’t fall for the bait. These are (mostly) not technology problems, but rather process problems, and technology isn’t the magic pill to driving more efficient processes. Regardless, less than 10% of what you find will focus specifically on sustainable practice or a sustainable end goal.

And yet, nearly every industrial business is thinking about Sustainability in a big way (more on that later).

So, here’s our proposal: Dispense with the premise of using IoT to achieve more efficient operations, and focus on the bigger picture. Let’s use the IoT to achieve, measure, and report on Sustainability.

When it comes to sustainable practice, industrial companies get a bad rap. In the public eye, people view manufacturing, energy, mining, and plastics companies, for example, as largely unsustainable. Some of this perception is informed by reality - 22% of global greenhouse gas emissions are produced by industry - but some is just naivety. Most people don’t understand the incredible challenge of operating and optimizing industrial assets that produce the vast majority of energy and goods that

our society finds beneficial. Still fewer are willing to part with all or even some of what these industries produce. Sustainability isn’t an industrial problem, it’s a global problem, and we all contribute.

And to be clear, Sustainability is not a new concept for industrial businesses. Many leaders have worked hard to implement sustainable practices in recent years to address concerns related to greenhouse gas emissions, deforestation, water scarcity, and more. The reality is that many - perhaps most - industrial companies care deeply about operating sustainably. In many ways, it makes financial sense. But on a more human level, most industrial leaders are just good people who do in fact care about helping people and protecting the environment.

Sustainability isn’t an industrial problem, it’s a global problem, and we all contribute.

What is relatively new for many industrial companies, however, is measuring and tracking sustainability metrics. Board members, executives, and directors are just beginning to learn how to formalize and standardize sustainable best practices with real-time field intelligence, and many need guidance. An executive at a large multinational publicly-traded industrial company recently told me that, when it comes to sustainability, they “are still learning how to count.”

Consider an oil and gas company like Chevron. The industry giant was founded in 1879, yet it wasn’t until 2002, over 120 years later, that Chevron produced its first Corporate Responsibility Report. Only in 2019 did the company start calling this document a “Sustainability Report.”

Note: we are not throwing Chevron under the bus. Chevron, like many industrial companies, is committed to achieving better sustainability outcomes and is meeting or exceeding standards in many cases. The point is that Sustainability - formally - is a relatively new focus area for most industrial businesses and one in which many operators have little experience.

Here we find an important trend: Corporate Responsibility is evolving beyond what we consider to be “regulatory compliance.” Sustainability is no longer about complying with the law. Global legislation, in many ways, is still playing catchup to the realities of climate change and other global impetuses for sustainable practice. Rather, this is about survival. This is a big deal for industrial companies. They know that to continue operating into the future, they need to be sustainable. Not only so they have a functional earth in which to continue operating, but also so they have the capital to operate.

This is no longer just about complying with the law. This is about survival.

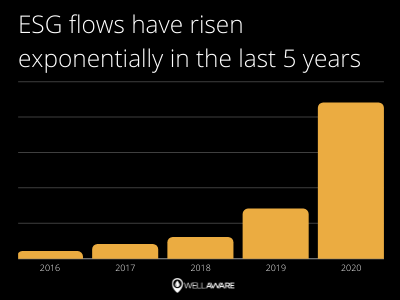

Many have heard of environmental, social, and corporate governance (ESG) investing, but perhaps few of us understand why we should pay attention. ESG investing is when investors choose stocks or funds consisting of companies that perform well on ESG issues. ESG investing is skyrocketing today; according to a recent CNBC report, assets held in US sustainable funds have QUADRUPLED in the last three years.

And don’t expect this to be a short-term fad. Morgan Stanley thinks ESG-investing will dominate the decade. Bain & Company makes it clear that investors see the social - and financial benefits - of making ESG investments. Investors are hyper-focused on putting money into top-ESG performers, and that mindsight seems like it’s here to stay.

Whether they like it or not, industrial leaders have to adapt to this new reality. If companies don’t invest in sustainable practices, they won’t win valuable investor capital that they need to not only continue operating, but also to create long-term value in a rapidly changing world. The race is on to attract sustainable-minded money, and forward-thinking executives know that the clock is ticking.

As the world turns more to renewable and carbon-free resources, oil and gas companies have to take steps today to avoid falling behind. Even though hydrocarbon demand isn’t expected to peak until roughly 2040, industrial organizations need to act now, especially given that twenty years is not a long time for businesses that have been operating for more than a century.

The race is on to attract sustainable-minded money, and forward-thinking executives know that the clock is ticking.

So, this brings us to our main point: With a focus on Sustainability, IoT might finally have its day.

At WellAware, we see the IoT as a multi-purpose tool in an industrial operator’s toolkit. Tools are meant to supply an advantage. In the case of levers and pulleys, for example, a mechanical advantage. The magnitude of the advantage depends on the type of tool and the scenario in which it’s deployed.

The IoT certainly has the potential to transform the ways that industrial companies operate. But we need to apply it in a way that will give us the most advantage. Most industrial companies don’t need much more advantage when it comes to efficiency. And that’s why most IoT projects right now have a negative ROI. But gather a room full of industrial executives, and 9 out of 10 will tell you they’ll take all the advantage they can get when it comes to being - and appearing - more sustainable (and the other one is on the phone with his Board Chair talking about ESG…)

The industrial executives who can craft the best sustainability narratives - backed by high-quality data - will win.

Perhaps the most exciting prospect of applying the IoT to solve sustainability problems is that - beyond just achieving sustainability gains - industrial companies can prove the effectiveness of their sustainable practices with cold, hard data. No more unfair criticisms. No more skepticism. Those who can craft the best sustainability narratives - backed by high-quality data - will win. They’ll attract investor capital and outpace the competition over the long haul. For the forward-thinking executive, that’s one heck of a return on investment (quite literally).

So, here’s what we think: IoT projects should focus on the problems that industrial companies care about most right now - and not just tangentially - but directly. When looking at IoT - think sustainability first.

Not sure where to begin? WellAware has helped hundreds of industrial companies achieve safer, more sustainable, more efficient operations by deploying IoT-based digital solutions, and measuring their performance under a service-level agreement. For ideas, visit https://wellaware.us/esg-performance/.

Like what you're reading? Sign up for updates!

Have a Question?