News, Insights, and more on Industrial IoT

Water transfer pumps are absolutely essential in the oil and gas, water and wastewater, petrochemical, and manufacturing industries. Really, we use water transfer pumps wherever there’s a LOT of water that needs to be moved really quickly.

Of course, water transfer pumps are hefty pieces of equipment. They’re expensive, consume a lot of energy, and require ongoing maintenance. No operator wants to have to replace a water transfer pump prematurely.

Consequently, many are interested in optimizing performance, maintaining pump efficiency, and lengthening pump life. To do this, operators have to monitor critical diagnostics and control outputs. Otherwise, it’s hard to know what (if anything) is off and when.

So, in this blog, we’ll explain:

Let’s tackle these in order.

One quick note: for this blog, we’re focusing on pumps with electric motors, not combustion engines (which some mobile water transfer pumps have).

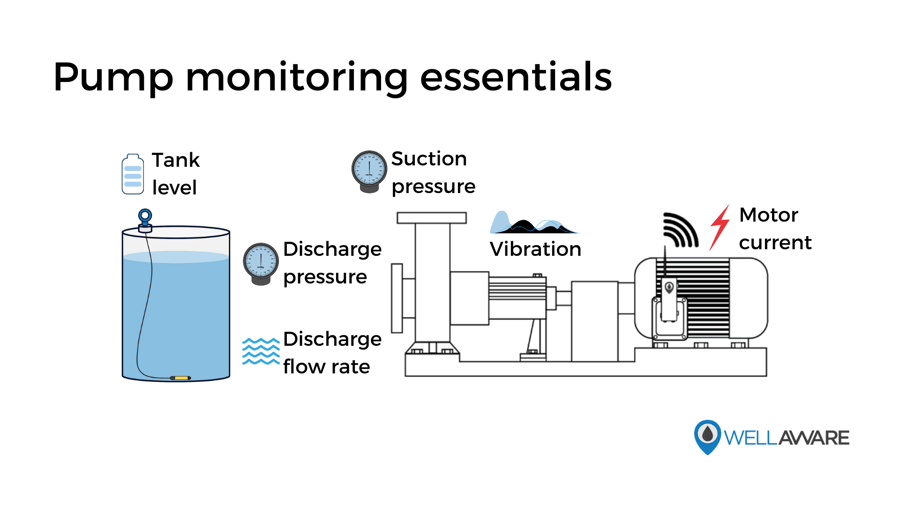

At a high level, here’s what you need to monitor to maximize transfer pump performance:

Each of these variables is important for a different reason.

Tank levels are crucial indicators of whether we’re successful in transferring large volumes of water from one location to another. In most cases, we transfer fluids between multiple industrial tanks or some other vessel type (e.g., pond, reservoir, etc.).

Regardless of the original source or destination, we need to know how much water exists in each to determine when transfer pumps should turn on and off. For instance, low levels at the source might mean you should turn transfer pumps off to avoid running the source dry. On the other side of the same coin, high fluid levels at the destination site might indicate you are about to overflow, another reason to turn your transfer pump off.

Suction pressure, discharge pressure, and flow rates are all important indicators of transfer pump efficiency. A drop in pressure differential or flow rate can signal that your pumps aren’t performing as efficiently as they should be, which is something you need to know ASAP.

Monitoring motor current is also useful for calculating true water transfer pump efficiency and energy consumption. If you have current, you can calculate electrical power consumed over time and, therefore, find out how much you are spending on energy. If you ever notice energy costs go up without seeing an increase in output, you’ve got a problem.

One of the clearest signs that you are overworking your transfer pumps is high motor temperature. Keep tabs on your motor temperature so you know when something seems off.

Another early indicator of wear or failure is water transfer pump vibration. Your pumps shouldn’t vibrate that much, so if they are, or if the intensity or frequency of vibration changes, there might be something wrong. Monitor vibration regularly to identify minor issues before they turn into bigger problems.

So we know what to monitor. The question now is “how?”

Here’s what you’ll need:

For a typical water transfer pump, you’ll want the following sensors for a full diagnostic picture:

If you need to connect the sensors listed above wirelessly, you’ll need wireless transmitters to get the data you collect back to a gateway. Chances are, you’ll go the wireless route because, quite frankly, it makes the most sense. Bluetooth, for example, makes for a reliable, secure wireless networking option. Wireless sensors work well for tank monitors, as they don’t get installed “on the pump” like other measurement devices might.

For hardwired sensors, you’ll at least need a PLC with inputs for all of your sensors. A PLC will process sensor outputs and convert readings into usable data.

If you do use wireless sensors (again, you probably should), you’ll need a gateway to collect wireless data. Sometimes, PLCs will have integrated gateways, which makes things easier if you aren’t hardwiring your sensors.

A network router or modem is necessary to connect your PLC and/or sensor gateways onto a network, such as WiFi or cellular. Routers and modems are what make your data available for access through the internet.

Be careful, though. Security is key here. We recommend you get a private APN on your network service provider and encrypt pump data to ensure none of your pumps or corporate networks are at risk of exposure.

Finally, you’ll need some type of software platform to view your sensor data. Your software should come with trending and alarming capabilities, so you can get notified of issues or anomalies, as well as summary views in the form of intuitive dashboards.

Map views are an added bonus if you can get GPS/location data from your network router. Because transfer pumps are often out in the field, we also suggest you pick a software vendor that offers mobile apps or tools for checking in on your pumps wherever you are.

Pump monitoring and control platforms should include controllers, connectivity, and software.

And now for the fun part.

Monitoring is great for performing diagnostics and discovering when something is wrong, but it’s the control part that empowers you to do something about it.

How you control your water transfer pumps depends on the types of motors they use. Water transfer pumps typically use alternating current (AC) but can range from single phase 110/120 VAC all the way to 3-phase 480 VAC or more. Many pumps have variable speed drives that allow you to modulate voltage frequencies to increase or decrease discharge rates.

The important thing is that you have a pump controller or PLC, a motor relay (if applicable), and a variable-frequency drive controller (if applicable). For single-speed motors, a simple solid-state relay will work for turning transfer pumps on and off. Variable-speed motors, on the other hand, require variable-frequency drive controllers.

Fortunately, many pumps come with pre-packaged controllers. In this case, all you need is to be able to connect to the controller using a communications protocol, such as Modbus. Your PLC should support native Modbus connections to existing pump controllers.

All the sensors we use to monitor transfer pumps can tell pump controllers how to manage our actual pumps. In other words, sensors can take the control work off our hands via automation. And this is where the real value is.

Here’s a simple example of automation in action: turning a transfer pump on when a tank level sensor indicates that the fluid level is above a certain height. Or, you can use pressure sensors to ensure your pumps maintain constant output pressure if that’s what you need. You can even integrate safety systems into your monitoring infrastructure to make sure pumps shut off to prevent safety incidents.

In reality, once you’ve got a handle on monitoring and control, how you implement automation is up to you! Automation can take many forms - the sky’s the limit! Be bold and explore different ways to automate pump performance to save your team time, money, and energy.

With this blog post, you now know how to monitor and control your water transfer pumps. You can improve pump efficiency, extend motor life, and reduce energy costs. Better yet, you can avoid safety and environmental risks that would otherwise create headaches for your business.

The challenge now lies in integrating everything we’ve discussed under one streamlined ecosystem. If that sounds like hard work, it’s because it is. That’s also why we designed a fully integrated pump monitoring and control package for modern operators.

Click here if you'd like to learn more about our pump solutions.

Like what you're reading? Sign up for updates!

Have a Question?