News, Insights, and more on Industrial IoT

The goal of any IoT project is to generate trustworthy data that empowers people and processes to deliver results. Yet, it can be intimidating to plunge right into such a new and exciting world. We get it.

The goal of any IoT project is to generate trustworthy data that empowers people and processes to deliver results. Yet, it can be intimidating to plunge right into such a new and exciting world. We get it.

For this reason, we see many organizations dip their toes in the IoT water with remote tank level monitoring (TLM). Tank monitoring is a “gateway drug” of sorts. It’s an intuitive, relatable way for IoT first-timers to try out remote monitoring.

And tanks are everywhere. We use liquids for so many essential manufacturing processes, from oil and gas production to wastewater treatment. Tanks are a critical part of the infrastructure.

When done well, tank level monitoring can provide a taste of just what IoT is capable of, and open your eyes to a world of IoT possibilities

But get it wrong, and you may never go back to IoT again. At WellAware, we think that would be a huge mistake. So, we are here to make sure you get it right - let’s get you hooked!

In this post, we’ll explain the three basic components of tank level monitoring and how each one can make or break your ability to take your business to the next level.

To get quality tank level data, you’ll need to invest in each of these layers.

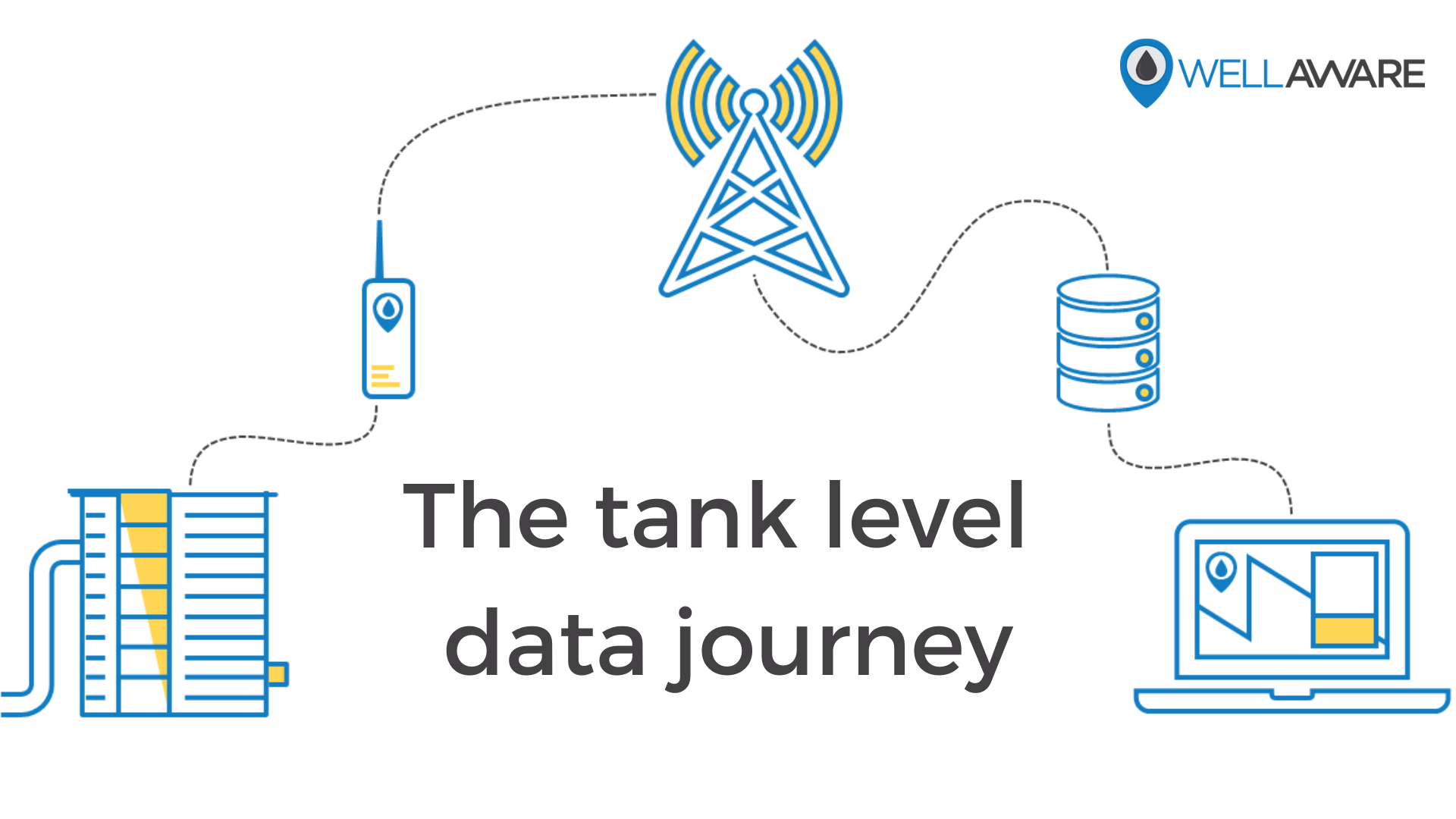

Tank level data must make a journey from your tanks all the way to your people and processes.

Making sure it gets there intact is critical to TLM success.

But here’s the thing: No amount of investment in tank level monitoring makes sense unless you can be totally confident that the tank data you get is accurate and reliable.

If you can’t trust the data, you’re doomed to a negative ROI.

You won’t be able to make savvy decisions that reduce costs, increase revenues, boost sustainability, and maximize safety. You’ll go back to doing things manually, and you’ll miss out on everything else the IoT has to offer.

We are here to make sure this doesn’t happen to you.

Let’s get started.

The foundation of any tank level monitoring system is the instrumentation used to sense and create data. Typically, tank level instrumentation involves some combination of sensors and transmitters. Operators install these devices on the inside of their liquids infrastructure.

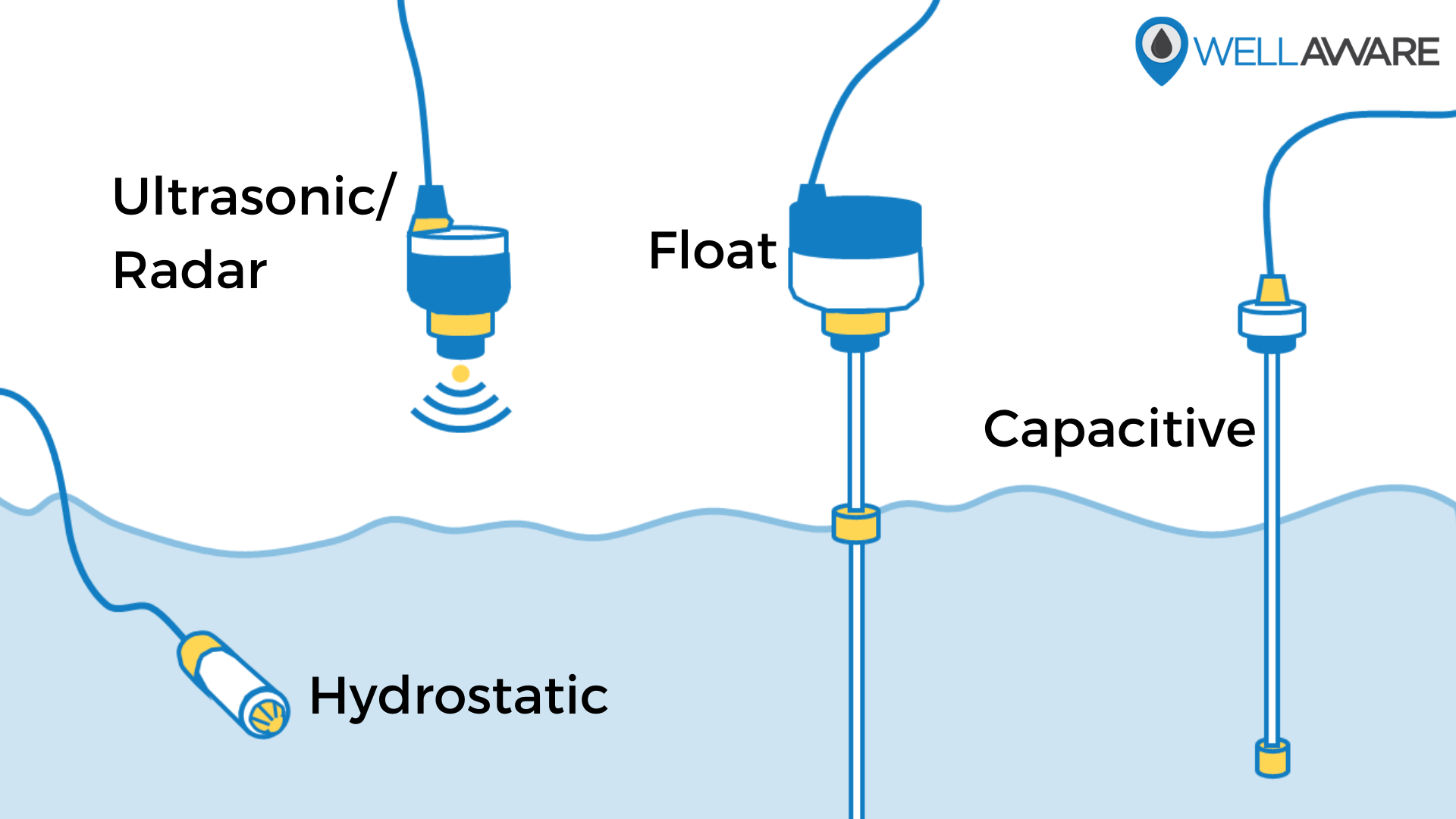

There are many different types of sensors out there. The most common are:

Different types of tank level sensors can be used for various applications.

Different types of tank level sensors can be used for various applications.

Each sensor type has its pros and cons.

Tank level sensors produce raw electrical signals that transmitters can then convert into usable data in the form of analog, serial, or high/low digital outputs. We are also seeing more transmitters hit the market with wireless and LPWAN capabilities as industrial IoT (IIoT) applications have increased in popularity.

Tank level sensors establish the data foundation. Without a good sensor and a precise transmitter, you won’t get the trustworthy data you are after, and your tank monitoring project will be DOA. You’ll need a sensor that’s accurate, reliable, and precise.

Not all sensors and transmitters are created equal. You’ll find a wide range of material quality (and pricing) in the market. Build quality is important because your instrumentation is often submerged in fluids. Your devices have to be compatible with your fluids. Otherwise, you risk spending way more than you expected because you’ll be replacing sensors every 6 months.

We’ve heard horror stories about sensor failure rates of up to 20%. If you do have to replace sensors every 6 months, imagine how that might affect your total cost of ownership? Plus, if you are constantly replacing sensors, you should expect your team to lack confidence in their accuracy.

The easiest way to assess tank level sensor reliability is to check the vendor warranty. Warranties are an expression of how confident vendors are that their instrumentation will generate trustworthy data over time. Make sure to evaluate vendor warranties carefully. When you see narrow definitions of “normal use” or leaky coverage, ask why.

If your manufacturer only offers you a 1-year warranty, consider how replacing your device every year would impact your total cost of ownership.

A short warranty periods indicates

a lack of confidence in the quality of the sensor

Bottom line: Don’t trust manufacturers who don’t trust their own products. Your IoT endeavors deserve better!

WellAware offers a lifetime warranty for tank level monitoring devices. How, you ask? Click here to learn more.

Lastly, your tank level monitoring instrumentation needs to be accurate.

Accuracy is usually reported as a factory-calibrated percentage of full scale or as a length of measurement. For instance, WellAware’s hydrostatic tank level sensors are accurate to 0.20% of full scale. In a 10 foot tank, that’s accuracy to about a quarter of an inch.

Once you’re satisfied with the reliability and accuracy of your tank level devices, you’ll also need to transport it in a secure and reliable way. With that in mind, let’s talk about networking.

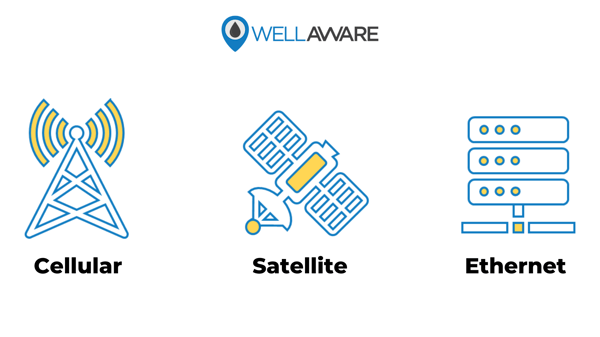

Networking is all about transporting tank level readings to centralized locations so we can start putting it to good use. Most modern tank level monitoring systems rely on public internet service providers (ISPs) to transport tank data using one of three technologies:

Theoretically, you could use a private 900 MHz radio network to transport tank level data to a SCADA server in your field office. And this is pretty common in legacy SCADA architecture. However, doing so is often more costly and less secure than using an ISP.

Radio networks also tend to create data silos across your organization, making life harder for the people and processes that need to access tank data. In the age of machine learning and AI-powered automation, radio isn’t the most efficient way to transport your data.

Regardless of the technology you choose, wireless tank level monitoring with public internet service providers is usually more cost effective and secure than private networks

You may be thinking that networking cost is your biggest concern here. In reality, it’s probably not. Transmitting data on public infrastructure is far less expensive than it used to be, and it keeps getting cheaper.

At scale, cellular costs can be less than $1/MB - with efficient IoT devices, you could easily spend less than $1/mo on wireless tank level monitoring. Now, if you don’t have cellular coverage, you may have to consider satellite networking, which can cost 100x more than cellular. So do your homework and check your network coverage.

Your mission to gather good tank level data falls apart if you can’t transport it from your tanks to your people, which is why reliable networking is crucial.

Network outages can easily disrupt your data pipelines, blocking people and processes from knowing what’s happening inside your tanks. Fortunately, public ISPs usually operate under service-level agreements (SLAs) that include uptime commitments, i.e., they guarantee availability or give you your money back. We like public ISPs over private networks because they take care of the messy stuff for you, like maintenance and troubleshooting.

Keep in mind, however, that some ISPs have different tiers of connectivity. If your infrastructure exists on a lower tier, you run the risk of getting “bumped” when demand is high.

WellAware tank level monitoring is certified to run on FirstNet, a federally mandated critical infrastructure network that gets top priority. Not all organizations qualify for FirstNet, but if you do, we highly recommend the network.

The great data you’ve collected and transported is only valuable if you can put it to work. So let’s talk about the last, and most exciting, component of a tank level monitoring system.

The last component in remote tank monitoring is data visualization and interaction. There are many powerful applications and technologies that can make this work easy.

For example, you could throw your data into a business intelligence tool, like Power BI or Spotfire, and call it a day. These platforms certainly help you visualize data in a structured way, and they are great for aggregating tank level data after-the-fact to arrive at conclusions.

However, keep in mind that the goal of real-time tank level monitoring is to put data to work, immediately. It’s not enough to just look back on what happened in our tanks last month. We want our people and processes to act on that knowledge in real-time to drive meaningful outcomes. To do so, we need the data visualization and interaction tools to get us there.

Everybody loves trends screens. And sure3, a good tank monitoring app should have a way to trend tank level data. But how many business operations managers have the time to look at trend screens all day to make real-time decisions? Zero. That’s how many.

We want our tank data to automatically trigger workflows and processes that enhance critical business operations. Otherwise, all the hard work to collect data, transport it, and store it is worthless.

A good tank monitoring app will offer more than just trend screens

A good tank monitoring app will offer more than just trend screens

on both web and native mobile applications

A good tank monitoring app has advanced alarming features, so you can notify critical stakeholders immediately if there’s an issue like a leak or an overflow.

Tank monitoring apps should also support automations. If that tank is about to overflow, you should automatically kick on the transfer pump.

And finally, a good remote tank monitoring system will let you integrate your tank data into systems and workflows you already use. Things like supply chain management, SCADA, ERP, and service ticketing.

But keep this in mind: bad tank data will absolutely wreak havoc at this stage. Inaccuracies can put the wrong processes in motion, which can have scary consequences for your organization. But don’t let that hold you back. Just make sure you get great tank data, and then put it to work.

At WellAware, we believe in the power of great tank level data. We want to see our customers change the way they do business because they are empowered by accurate, reliable tank data that lets them take action. That’s why our tank level monitors come with a lifetime warranty and our tank level data comes with a quality guarantee.

In full transparency, we want you to get hooked on the IoT. It’s a total game-changer. And one of the best ways to break the ice is with remote tank level monitoring.

Check out our tank level monitoring web page to get started. You won’t regret it.

Like what you're reading? Sign up for updates!

Have a Question?